| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : MCLLROY

Model Number : MCL930

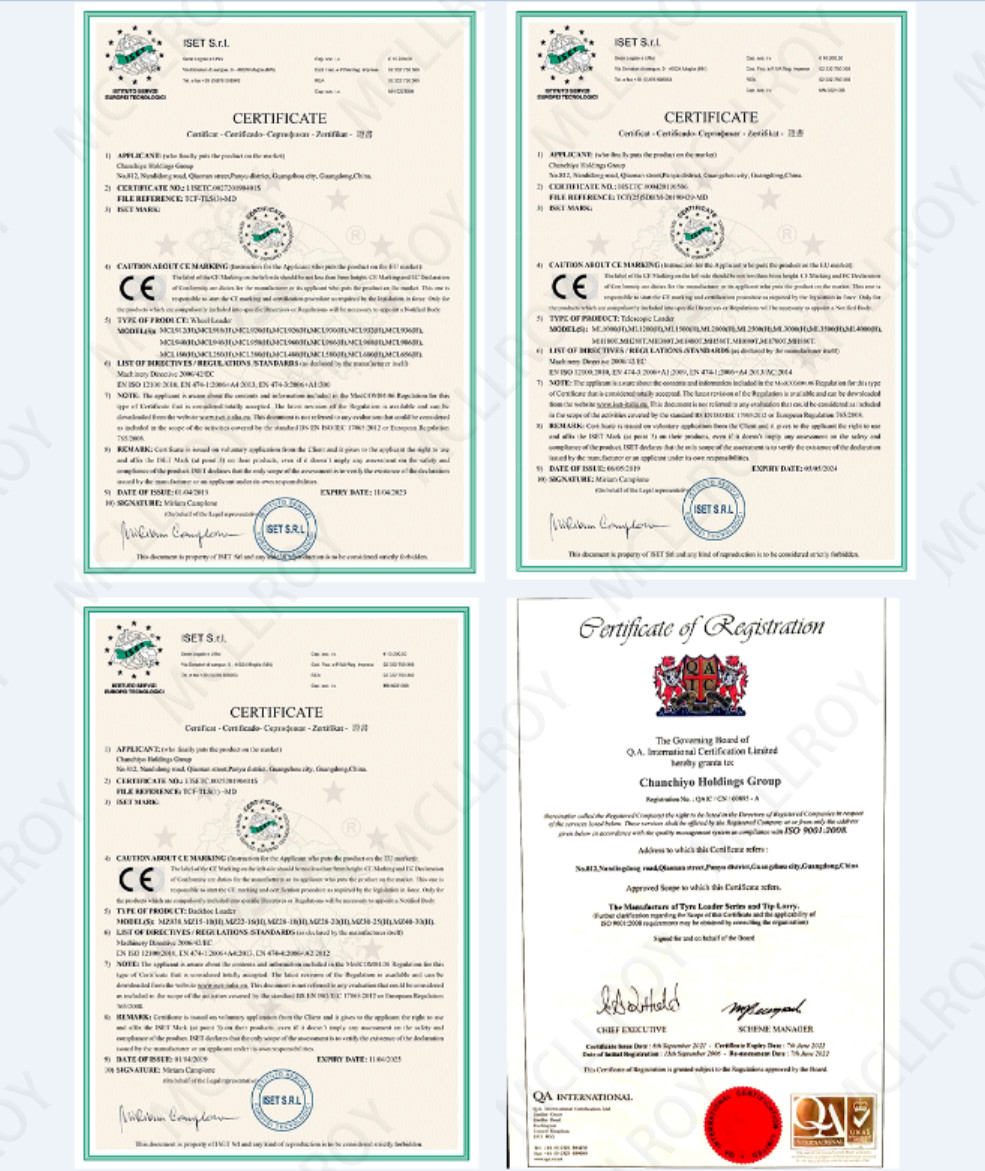

Certification : CE/ISO

Place of Origin : China

MOQ : 1 Unit

Price : $4000-6000/Unit

Payment Terms : 30% T / T in advance and 70% balance before shipment / 100% L / C at sight

Supply Ability : 100 Units / Month

Delivery Time : 5-8 days

Packaging Details : Nude,Fasten Packing ,2 or 3 Units loaded in one 40HQ

Engine Model : Yun Nei 490

RPM : 2400

Rated Power : 42 kW

Emissions : EU Stage II

Operating Weight : 3500 kg

Rated Load : 1600 kg

1. Products Description of MCLLROY Wheel Loader

The MCLLROY Wheel Loader is the ideal choice for those in need of a compact but powerful machine, boasting remarkable lifting and dumping heights and a considerable breakout force when equipped with buckets or pallet forks, ensuring maximum productivity.

To power this loader, we utilize a reliable Yunnei engine. Since numerous developing nations currently do not have stringent regulations concerning engine emissions, we find that using Yunnei engines is a fitting option for exporting to Southeast Asia. These engines are known for their consistent performance, affordability, and are considered the most cost-effective engine option for small loaders.

2. Specification

| MCL 930 | |

| Engine Model | Yun Nei 490 |

| RPM | 2400 |

| Rated Power | 42 kW |

| Emissions | EU Stage II |

| Operating Weight | 3500 kg |

| Rated Load | 1600 kg |

3. Details and Advantages of MCLLROY Compact Wheel Loader

1) Employing the highly efficient and durable Yunnei China II engine, renowned for its exceptional performance in agricultural and small-scale construction projects.

2) Featuring a cast steel small hub reduction axle, which is both classic and robust.

3) The horizontal frame design has been skillfully engineered to protect the gearbox and steering cylinder.

4) With a high chassis and a minimum ground clearance of 29 cm, the loader is well-suited for mountainous, agricultural, and mining operations.

5) The hydraulic system is stable and reliable, with triple-wire hydraulic hoses that facilitate short cycle times and streamlined operation.

6)Dual high and low speed gearboxes and handles for quick switching between work and travel modes.

4.Production lines of MCLLROY Wheel Loader

A complete production process mainly includes: material procurement-steel plate cutting-welding-spray painting -drying-assembly-inspection

Welding is a crucial process in the manufacturing industry, as it joins metal parts together to create a finished product. The quality of the welding can greatly affect the integrity and strength of the final product.

Manual welding requires skilled workers who have experience and knowledge in welding techniques. However, the finished product may have variations in quality due to factors such as human error and fatigue. On the other hand, robot welding, if well-adjusted, can provide more stable and consistent quality.

A good weld is one that is done at once and has a seam no greater than 1mm. Fair welding may have break points, while bad welding may result in a seam that is too wide. In such cases, workers may have to stuff iron into the side of the seam and weld another layer outside. The appearance of the finished product may not reveal these differences, but they can greatly affect the product's integrity and strength.

Our company uses robot welding, with a total of 10 robots currently in use. We take pride in our high-quality welding, which is evident in the pictures comparing our welding to that of other companies. Our welding has no break points and provides a strong and durable final product.

CM Issued

|

|

1600kg Load Little Compact Wheel Loaders CVT 265 Torque Converter Transmission Images |